Very Narrow Aisle (VNA) Inspections

Thorough examinations are crucial for VNA forklift trucks to detect and address hidden safety issues. Competent engineers verify the functionality of safety devices like aisle sensors and wire guidance systems, ensuring operational safety standards are upheld.

Comprehensive Guide to Very Narrow Aisle (VNA) Forklift Trucks Thorough Examinations

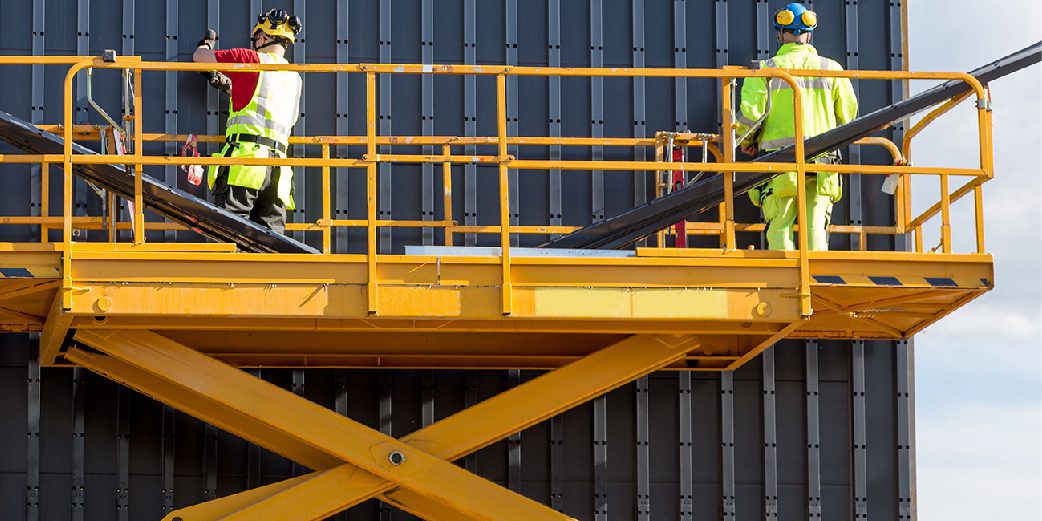

Very Narrow Aisle (VNA) forklift trucks are a popular choice in warehouses and distribution centres for their ability to operate in tight spaces, enhancing manoeuvrability. However, the increased complexity and safety considerations associated with VNA trucks necessitate thorough examinations conducted by fully trained and specialist engineers to ensure safe and efficient operations.

Importance of Thorough Examinations for VNA Forklift Trucks

Thorough examinations are crucial for VNA forklift trucks to identify and address potential safety issues, many of which may be invisible to operators. By having competent engineers conduct thorough inspections, the functionality of safety devices, such as aisle sensors and wire guidance systems, can be verified to uphold operational safety standards.

Conducting Thorough Examinations for VNA Forklift Trucks

Our engineers at Statutory Inspections are equipped with the expertise to troubleshoot safety issues and ensure the correct functioning of safety devices on VNA trucks. Installation inspections are also conducted to verify proper assembly and parameter settings, guaranteeing operational integrity and safety compliance.

Benefits of Choosing Us for VNA Forklift Trucks Thorough Examinations

-

Technical Expertise: Our engineers possess the necessary licenses to drive VNA trucks, enabling comprehensive testing of steer guidance systems, end-of-aisle slow down mechanisms, and safety features to ensure optimal functionality.

-

Regulatory Compliance: VNA trucks, along with Mid and High-Level Order Pickers (M/HLOP), require thorough examinations before initial use and every 6 months thereafter, in accordance with LOLER regulations.

-

Early Fault Detection: Thorough examinations help detect potential issues early on, preventing costly downtime and safety hazards that may arise from undetected faults.

-

High-Quality Service: We prioritise quality by conducting inspections in-house, ensuring a consistent and reliable service standard that prioritises safety and compliance.

By choosing Statutory Inspections for your VNA forklift trucks’ thorough examinations, you are opting for a team of fully trained and experienced engineers dedicated to upholding safety standards and operational efficiency. Our commitment to providing visual identification, timely inspections, and accessible reports ensures peace of mind for our clients, eliminating concerns about compliance and documentation management.

How long does the inspection take?

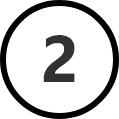

It can take up to 2 hours to fully inspect the equipment including driving in all aisles it will be operating in. We test and check steer guidance systems, end of aisle slow down, speed reduction or automatic stop and that all controls and safety systems are functioning as intended. Our engineers are fully trained in VNA inspection and have licences to drive the equipment including abseil descent. All equipment used to lift people needs to be inspected every 6 months, therefore VNA’s & M/HLOP’s are required by LOLER to have a Thorough Examination every 6 months.

Why should a Thorough Examination be carried out?

A VNA can face various operational issues that may escape the driver’s notice, thanks to the truck’s automated safety mechanisms. Our Engineers specialise in identifying these faults promptly to prevent the equipment from being taken out of service, which could lead to increased costs and downtime.

How it works

Arrange

Easily book, manage, and securely store your Thorough Examination inspection certificates through our custom-designed online portal.

Inspect

An engineer from our team will conduct a comprehensive inspection by LOLER and PUWER regulations to ensure the safety and compliance of your equipment.

Report

Following the completion of an inspection, a Thorough Examination report will be promptly issued. All docs, including the report, is available through our secure portal.

No Contract

You're not bound by a long-term contract with us. We're here to support your business whenever you need us.

Choosing Statutory Inspections for your VNA and M/HLOP’s Thorough Examinations:

- Fully trained and experienced engineers.

- High-quality service. We don’t subcontract our inspection ensuring continuous high-quality service.

- Visual identification to show equipment is safe and when the next inspection is due.

- Access to your reports and certificates whenever you need them, never worry about losing inspection documents again!

High Standards

Our unwavering commitment is to deliver a first-class service that offers excellent value for money. By investing in a team of highly skilled and experienced engineers, we ensure that inspections are completed with professionalism and efficiency. This approach is designed to minimise any disruption and downtime to your operations, allowing for seamless business continuity.

ISO 9001:2015

ISO 9001 is the internationally recognised Quality Management System (QMS) standard. Defining commitment to creating services in accordance with pre-defined standards.

UK MHA

The UK Material Handling Association (UKMHA) is a non-profit organisation representing all sectors of the UK material handling industry, committed to enhancing standards and providing audit, advisory, and training services

SafeContractor

SafeContractor is the UK's leading Health and Safety Accreditation, supporting you by helping to demonstrate a commitment to sustainable and ethical practices.

Thorough Examinations

A Thorough Examination is a mandatory inspection to ensure the safety of lift trucks by checking their mechanical parts, similar to a car MOT. Go digital, go green and protect the trees.

What we inspect

Explore Statutory Inspections Resources and tips

Why inspecting electric truck batteries is crucial

Electric trucks have become increasingly popular in recent years due to their efficiency and...

What to look for when buying a used forklift

What to Look for When Buying a Used Forklift: A Pre-Purchase Inspection Guide Are you in the...

Forklifts: How much can you legally lift?

When it comes to lifting equipment, it is important to understand the legal requirements and...